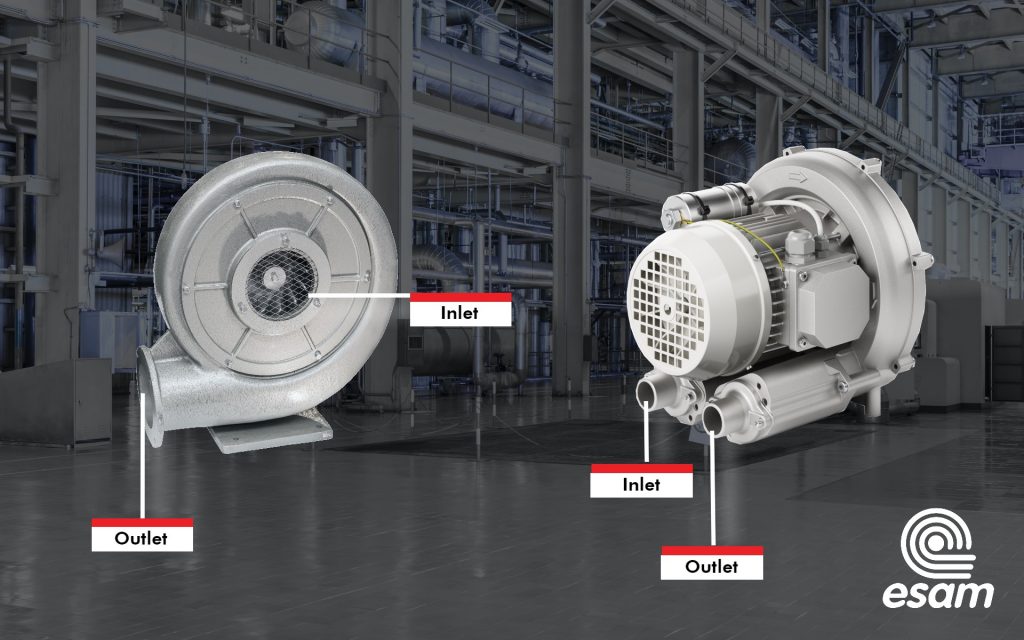

ESAM supplies side channel blowers (also known as regenerative blowers) that can sometimes be confused with centrifugal blowers. Centrifugal blowers and side channel blowers are both types of mechanical equipment used to transport air or other gases. Yet, it is important to understand their similarities and key differences to choose the right equipment for your application.

Both types of equipment move air using an impeller, where the air enters the inlet travelling with the impeller before being exhausted at the outlet. Other than that, they are very different, starting from their configuration design.

The design of the blowers

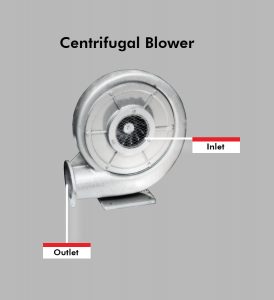

The difference in construction between a centrifugal and a side channel blower makes it easy to tell the two apart visually. A centrifugal blower is configured so that the inlet and outlet are perpendicular, with the inlet feeding air into the centre of the impeller and the outlet lateral to the rotation of the impeller. In a side channel blower, the inlet and outlet are parallel, with both positioned perpendicular to the rotation of the impeller.

Centrifugal blowers

As the name suggests, centrifugal blowers move air through centrifugal action. These blowers have a spinning impeller to generate airflow, where the air is drawn into the centre of the impeller and then forced outward by centrifugal force. Centrifugal blowers are commonly used in heating, ventilation, air conditioning (HVAC) systems and many industrial processes. They are typically more efficient at higher airflow rates and have relatively low pressure.

Side channel blowers

Side channel blowers use rotating impellers to generate a pair of vortexes, forcing the air to advance in a spiral motion and continuously compressing the air to build pressure from the moment it enters the inlet to the time of leaving the outlet. Side channel blowers are often used in applications where a low air volume needs to be moved at high pressure, such as in pond aeration in aquaculture.

Best Applications

| Centrifugal Blowers | For applications where high flow at low pressures is required

HVAC, ovens, tunnels, filter flushing, gas boosting, dust control, air conveyor systems, fluid bed aerators, etc. |

| Side Channel Blowers | For applications where moderate flows with significant pressure are needed

Aquatics (spas and pools), pond aeration, vacuum evacuation of gases and dust, packaging, drying processes in wine production, pneumatic conveying, sewage aeration, etc. |

In summary, centrifugal blowers are considered low-pressure, high-flow blowers, while side channel blowers are high-pressure, low-flow blowers. These fundamental characteristics help dictate the types of applications to which they are suited. One of the great benefits of side channel blowers is that they can act as either pressure or vacuum blowers.

To learn more about how our low-maintenance equipment can benefit your projects, read our story here.

Alternatively, call us now on 03 9484 5719.

ESAM Side Channel Blowers

Made in Italy – designed and produced in Italy to ISO 9001 standards.

Warranty – 5-year warranty.

Quality – our blowers are made to the highest standards, using robust, quality materials.

Low maintenance – our blowers are reliable and need minimal maintenance.

Quality assured and individually tested TWICE – every individual ESAM side channel blower is rigorously tested under maximum-rated conditions of its likely application. Each unit is tested by the manufacturer in Italy and again in Australia before undergoing quality assurance for dispatch from our Melbourne warehouse.

Service – specialised local in-house technical team for service and customer support.