Good things may take a little time, but great things can take longer. This is certainly true for the reputation that the chef brings to the meal, restaurant, and even the food and beverage industry.

The Australian Government aims to double the value of Food and Beverage manufacturing by 2030, and one of the key areas to benefit from this is Australia’s reputable chicken meat industry.

According to the Australian Bureau of Agricultural and Resource Economics and Sciences (ABARES), almost 1.3 million tonnes of chicken meat was produced in 2020/21 for consumption. During that year, the consumption of chicken per capita was 47.8kg per person, compared to 27.7kg for pig meat, and 20.1kg for beef and veal.

With such a fast-growing industry, strict importing protocols have been established to protect quality standards, presenting challenges for overseas poultry producers. As a result, almost all chicken meat consumed in Australia are grown domestically.

Supporting this key industry for almost 20 years, ESAM has been providing quality air solutions to facilitate various stages of chicken meat production.

Some examples include:

Vacuum systems for egg handling

Pneumatic bulk feed delivery

Feather removal process

Vacuum Systems for Egg Handling

Vacuum egg lift systems are specially designed to safely transport eggs via suction cups, which helps to streamline operations for egg handling efficiency. The side channel blower supplies this system with precise suction power that greatly reduces labour costs and time associated with the transfer of eggs.

Pneumatic Bulk Feed Delivery

ESAM air technology provides the optimum performance to systems for transferring animal feed. Our side channel blowers and oil-free air compressors are designed to supply air to transport bulk feed products to specifications. We provide configurations to deliver precise pressure and flow rate to suit poultry farm operations.

Feather Removal Process

One of the key stages of chicken meat preparation is the defeathering process. Due to soil contact with feathers, it is critical to minimise cross-contamination through heated water tanks. Blowers are installed within the tanks to generate turbulence to assist with the loosening of feathers, ensuring the best defeathering results.

From chicken breeding, rearing, processing, through to distributing, ESAM understands that consumer wellbeing is paramount to this industry. Applying expert precision to rigorous requirements, ESAM continuously pursues 100% reliability to reduce any risks of contamination caused by downtime.

ESAM’s reputation: 35 years in the making

A global industry requires support from reputable partners, one that demonstrates trustworthiness and reliability. This reputation helps clients place confidence behind the name when collaborating in business. With more than 35 years of history behind the ESAM name, providing reliable support from our Australian in-house technical team, we are well-positioned as one of the world leaders in air technology.

At ESAM, we take care of our quality, so our reputation takes care of itself.

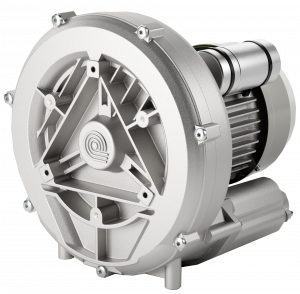

ESAM Side Channel Blowers

Made in Italy – designed and produced in Italy to ISO 9001 standards.

Warranty – our blowers come with a 5-year warranty.

Quality – our blowers are made to the highest standards, using robust, quality materials.

Low maintenance – our blowers are reliable and need minimal maintenance.

Quality assured and individually tested TWICE – every individual ESAM side channel blower is rigorously tested under conditions at the extremes of its likely application. Each unit is tested by the manufacturer in Italy, and again in Australia, before undergoing quality assurance for dispatch from our Melbourne warehouse.

Service – specialised local in-house technical team for service and customer support.

To find out more, call us now on 03 9484 5719 or visit www.esam.com.au.